Demonstrator-JLR: Dry Dilute Combustion achievements

Follow the links below to find more results related to the Dry Dilute Combustion Demonstrator

Deliverables

D4.1 Concept Specification Report

D4.2 Engine Combustion And VGT Design Report

D4.3 Control System Design Report

D4.4 Combustion System Development Report

D4.5 Engine Development Report-2019-07-29

D4.6 FINAL-Vehicle Development-2019.12.20

The full poster and presentation

Engine Concept

- Revised intake ports and piston crown design to offer high levels of charge motion

- Increased compression ratio

- Inclusion of Low-Pressure-Loop Exhaust Gas Recirculation (LP-EGR) system

- High-pressure (up to 350 bar) fuel injection system

- Revised fuel injector spray pattern

- High-energy ignition system

- Bespoke control system featuring closed-loop combustion control

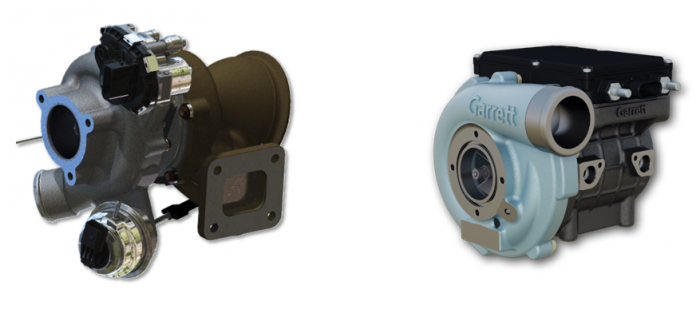

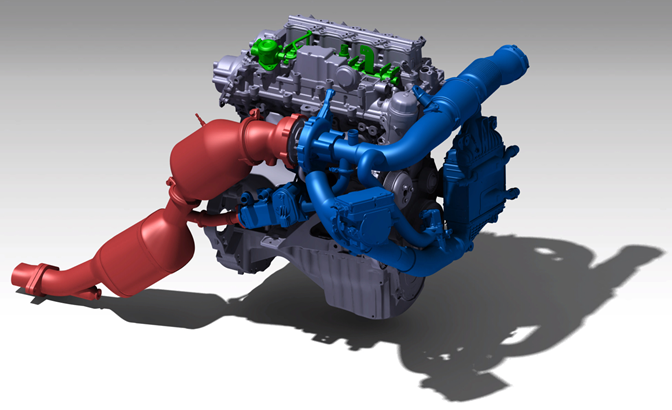

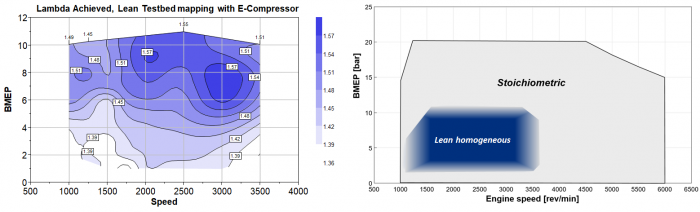

Boosting System

- Variable-Nozzle-Turbine (VNTTM) turbocharger with integrated wastegate technology

- Supported by an electric compressor for rapid lean transitions and extended lean operation

Engine Technology

- Fully variable displacement oil pump

- Fully variable intake valve timing and lift

- Variable exhaust valve timing

- Piston cooling jets

- Split-cooling system for faster warm-up

- Integrated exhaust manifold

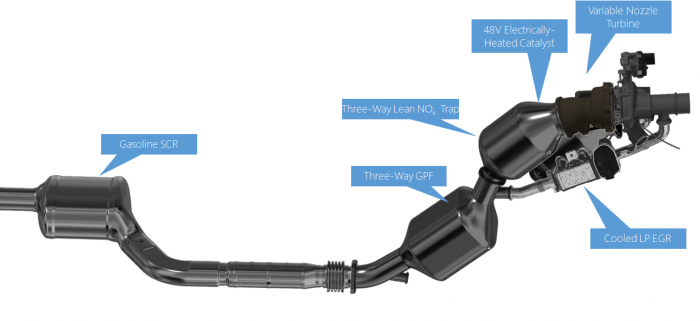

Engine Aftertreatment System

- Electrically-heated catalyst for improved cold start emissions

- Three-Way / Lean NOx Trap catalyst with downstream Gasoline Particulate Filter

- Urea-dosed Gasoline Selective Catalytic Reduction catalyst

Combustion System

- Engine designed to operate in both stoichiometric and in lean combustion modes

- Changes made to the combustion system enable rapid combustion despite lean conditions

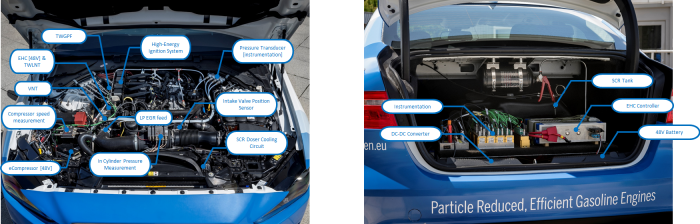

Vehicle Packaging

- Concept designed to fit in vehicle engine bay

- Engine and exhaust system fully packaged in vehicle

- 48V system packaged in boot