Demonstrator-MERC: Exhaust gas condensation system for high water injection rates in gasoline engines

Follow the links below to find more results related to the Exhaust gas condensation system for high water injection rates in gasoline engines

Deliverables:

D3.2 Layout Combustion System CFD

D3.6 on the water & gasoline spray investigations and PWI vs. DWI engine investigation

The full poster

Motivation

- Reduction of CO2 emissions by increased engine compression ratio (CR)

- High water to fuel ratios for Direct Water Injection (DWI) to avoid engine knock limitation for increased engine efficiency

- Water recovery from exhaust gas condensation as enabler for self-sustaining water injection and increase of customer acceptance for water injection systems

- Stoichiometric air/fuel ratio in entire engine map for low CO2 emissions and RDE compliance

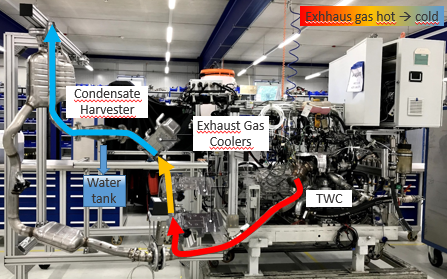

Engine Dyno Configuration

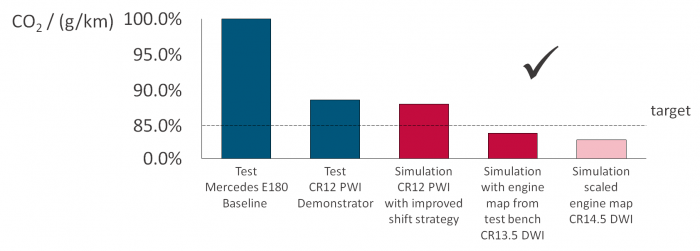

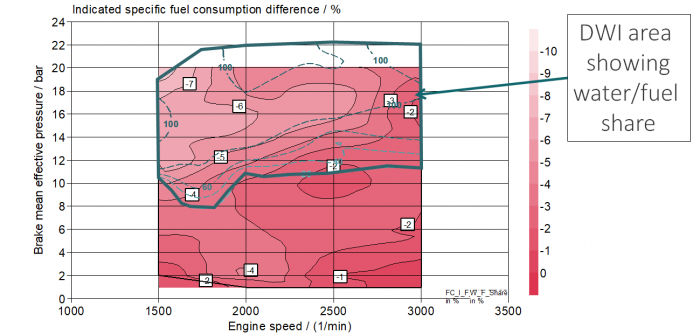

Reduction of Fuel Consumption with DWI and CR 13.5:1

Relative difference to engine with PWI and CR 12:1 engine testing results.

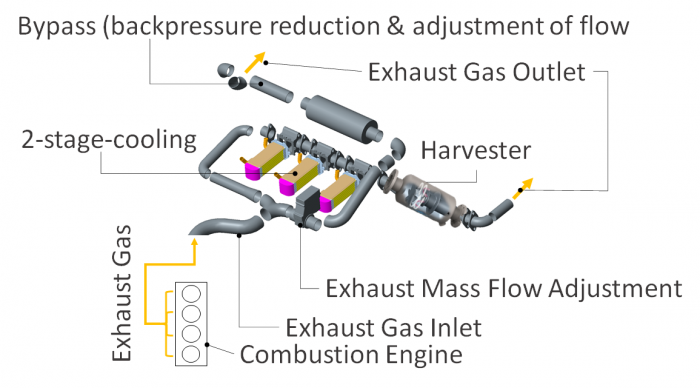

Package & Vehicle Integration

Condensate system can be integrated in OEM vehicle packages

Results of Water Injection & Condensate Harvesting Efficiency & Quality

- CO2 improvement of >15% can be realized

- Harvesting of more condensate than injected is possible

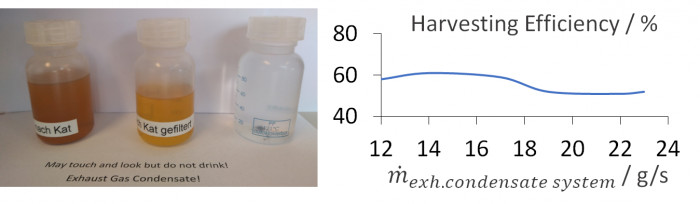

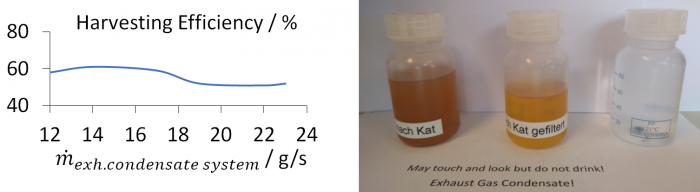

- Harvesting efficiency investigated and >60 %

- Condensate quality after GPF nearly free of particles, neutral pH-values – no disadvantages in combustion or emission topics

- Different condensate harvesting points compared – best position after exhaust aftertreatment (GPF)

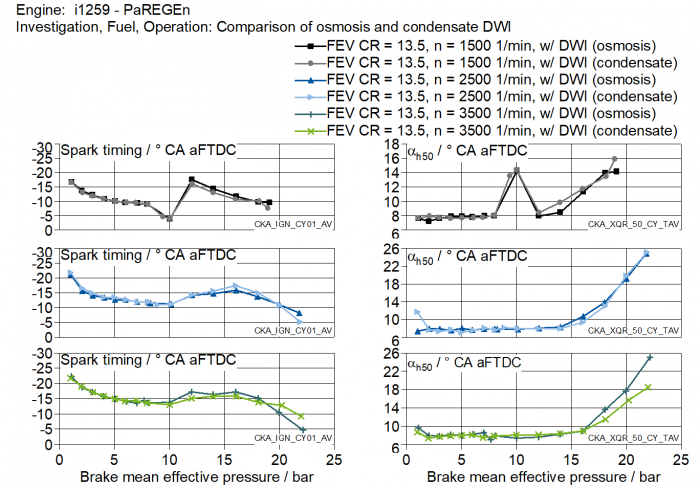

- Same advantages for emissions and combustion for condensate compared with distilled water