Demonstrator: Lean-NOx Emissions Aftertreatment System with Low Particle Number down-to-10nm

Follow the links below to find more results related to the Lean-NOx Emissions Aftertreatment System with Low Particle Number down-to-10nm

Deliverable:

D2.4 Final Lean NOx Low PN Aftertreatment System

The full poster and presentation

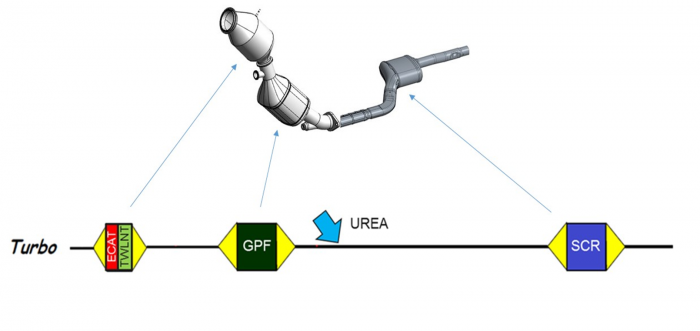

System Overview

Aftertreatment system must provide excellent emissions control under lean (λ>1) conditions, whilst being thermally durable to withstand high temperatures under peak-load λ=1 conditions. Final system design comprised.

- Three-Way Lean NOx Trap (TWLNT) – three-way (CO, HC, NOx) and Lean NOx trap technologies combined for stoichiometric performance and lean NOx conversion. Coated on electrically-heated catalyst (EHC) substrate for good cold-start performance.

- Gasoline Particulate Filter (GPF) – High filtration efficiency (FiE) for particles down to 10nm in size. Three-way coating technology with additional NO2-make function.

- Selective Catalytic Reduction (SCR) catalyst – lean NOx conversion with ammonia (urea) dosing. May also store/convert NH3 formed over upstream catalysts.

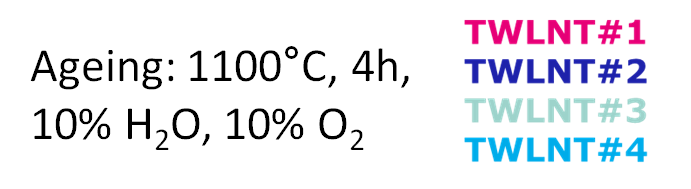

TWLNT development

As the starter catalyst in the system, technology must maintain excellent TWC performance and lean NOx storage following exposure to temperatures potentially >1000°C. Following high-temperature ageing, TWLNT1 showed the highest NOx storage and TWC performance.

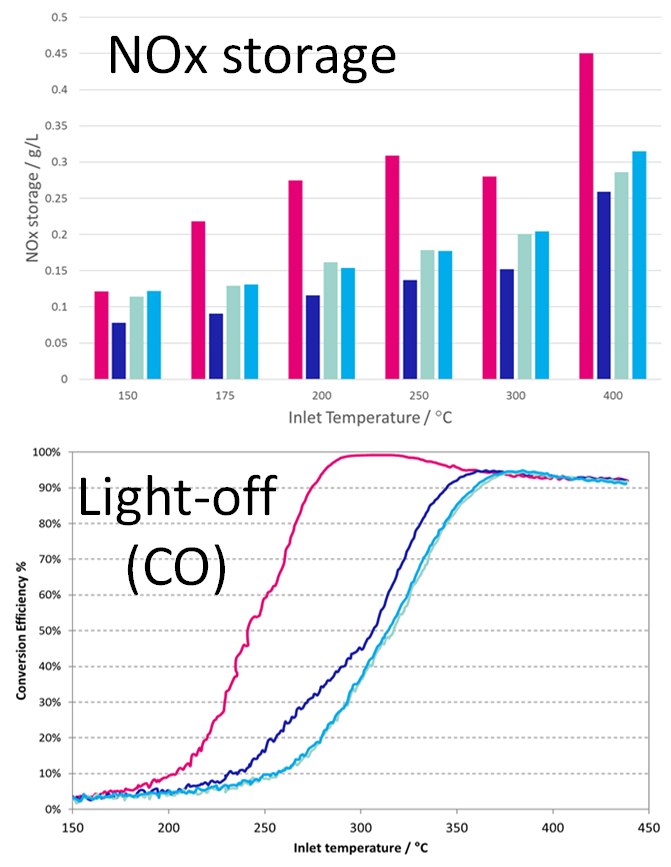

GPF technology with high FiE down to 10nm

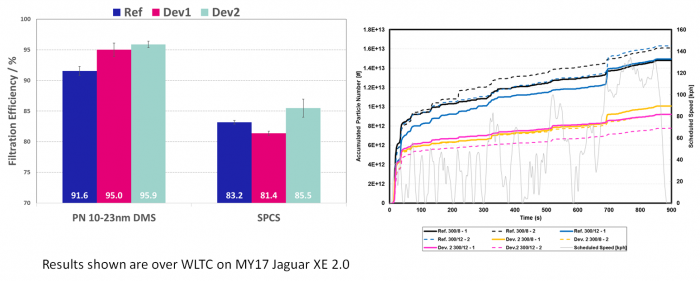

Following preliminary screening, Dev 1 and Dev2 were taken forward for chassis-dynamometer evaluation, based on filtration performance and backpressure.

Particle number evaluated on vehicle using Horiba SPCS (≥23nm) and Cambustion DMS500 (10-23nm). Dev2 demonstrated best FiE % over all particle-size ranges – verified on 300/8 and 300/12 substrates.

Optimisation of SCR performance

- An iron-based SCR catalyst was chosen because of its tolerance of rich/stoichiometric conditions and high exhaust temperatures.

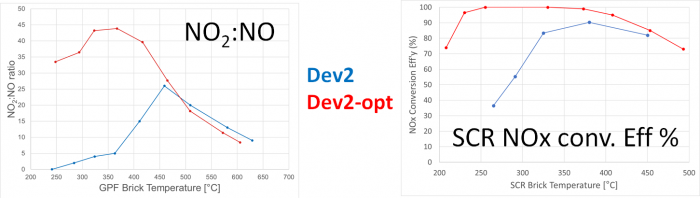

- NOx conversion efficiency at low temperatures strongly dependent on NO2:NO ratio.

- Initial trials indicated that low NO2 concentrations at GPF outlet were limiting peak NOx conversion over SCR.

- Further optimisation of the Dev2 technology led to higher NO2-make and improved SCR conversion efficiencies.

TWLNT coated on 48V electrically-heated catalyst substrate for rapid response from cold-start conditions.

Conclusions

- Aftertreatment system developed for lean-burn gasoline demonstration vehicle.

- Selected catalyst technologies designed to be thermally robust under high loads/temperatures.

- Optimised GPF technology for high FiE down to 10nm and enhanced lean NO2-make, enabling improved SCR conversion efficiencies.