Demonstrator-JLR: The coupling of Advanced Gasoline Combustion & Ultra Responsive Boost System to support CO2 Emission Targets

Follow the links below to find more results related to the coupling of Advanced Gasoline Combustion & Ultra Responsive Boost System to support CO2 Emission Targets

Deliverable:

D1.11 3D CFD simulation method for in-cylinder soot simulation

D3.2 Layout Combustion System CFD

D3.6 on the water & gasoline spray investigations and PWI vs. DWI engine investigation

Publications: zenodo

The full poster and presentation

Lean Combustion Requires

- Higher air delivery to the cylinders

- Efficient turbocharging at low exhaust gas enthalpy conditions

- Swift transient response to air mass flow demand (lean switch)

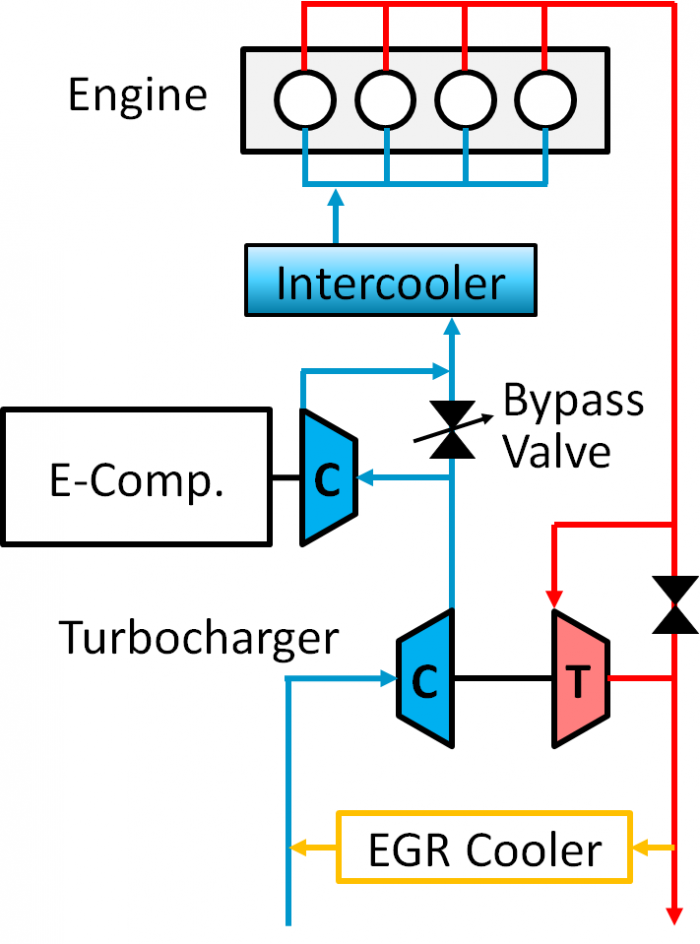

Selected Boosting Architecture

- Variable geometry/nozzle turbine (VNTTM) with integrated wastegate

- 48V Electric compressor

GEN2 E-Compressor

Electric Compressor downstream of VNT turbo

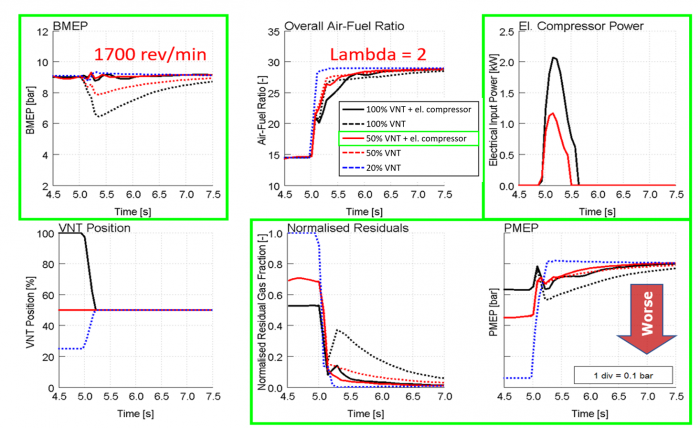

Air-Fuel Ratio Switch

Achieved Performance

- 175 Nm steady state torque under lean operation (11 bar BMEP)

- Seamless lambda switch in less than 0.5 s (1700 rpm, stoich. to λ = 2 in simulation, λ = 1.6 on engine)

- Turbine efficiency increase by up to 3pts thanks to design optimization

- Gen2 E-Compressor with peak power of up to 8.5 kW